LnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfSAjdGJjc3MgLndwLWJsb2NrLWltYWdlLnRiLWltYWdlW2RhdGEtdG9vbHNldC1ibG9ja3MtaW1hZ2U9Ijc0Zjg1N2JhNDk4ZTNjOTQ2NjQ0ZGJiODk4ZTkxZTJhIl0geyBtYXgtd2lkdGg6IDEwMCU7IH0gI3RiY3NzIC53cC1ibG9jay1pbWFnZS50Yi1pbWFnZVtkYXRhLXRvb2xzZXQtYmxvY2tzLWltYWdlPSI3NGY4NTdiYTQ5OGUzYzk0NjY0NGRiYjg5OGU5MWUyYSJdIGltZyB7IHBhZGRpbmctcmlnaHQ6IDEwcHg7cGFkZGluZy1sZWZ0OiAxMHB4OyB9IC50Yi1pbWFnZXtwb3NpdGlvbjpyZWxhdGl2ZTt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS53cC1ibG9jay1pbWFnZSAudGItaW1hZ2UuYWxpZ25jZW50ZXJ7bWFyZ2luLWxlZnQ6YXV0bzttYXJnaW4tcmlnaHQ6YXV0b30udGItaW1hZ2UgaW1ne21heC13aWR0aDoxMDAlO2hlaWdodDphdXRvO3dpZHRoOmF1dG87dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdle2Rpc3BsYXk6dGFibGV9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbntkaXNwbGF5OnRhYmxlLWNhcHRpb247Y2FwdGlvbi1zaWRlOmJvdHRvbX0gI3RiY3NzIC53cC1ibG9jay1pbWFnZS50Yi1pbWFnZVtkYXRhLXRvb2xzZXQtYmxvY2tzLWltYWdlPSI3ZTJjMTU2MWY3ODkxY2QyNzRiYTA4NGRjNGNjMDMzMyJdIHsgbWF4LXdpZHRoOiAxMDAlOyB9ICN0YmNzcyAud3AtYmxvY2staW1hZ2UudGItaW1hZ2VbZGF0YS10b29sc2V0LWJsb2Nrcy1pbWFnZT0iN2UyYzE1NjFmNzg5MWNkMjc0YmEwODRkYzRjYzAzMzMiXSBpbWcgeyBwYWRkaW5nLXJpZ2h0OiAxMHB4O3BhZGRpbmctbGVmdDogMTBweDsgfSAudGItaW1hZ2V7cG9zaXRpb246cmVsYXRpdmU7dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0ud3AtYmxvY2staW1hZ2UgLnRiLWltYWdlLmFsaWduY2VudGVye21hcmdpbi1sZWZ0OmF1dG87bWFyZ2luLXJpZ2h0OmF1dG99LnRiLWltYWdlIGltZ3ttYXgtd2lkdGg6MTAwJTtoZWlnaHQ6YXV0bzt3aWR0aDphdXRvO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZXtkaXNwbGF5OnRhYmxlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2UgLnRiLWltYWdlLWNhcHRpb257ZGlzcGxheTp0YWJsZS1jYXB0aW9uO2NhcHRpb24tc2lkZTpib3R0b219ICN0YmNzcyAud3AtYmxvY2staW1hZ2UudGItaW1hZ2VbZGF0YS10b29sc2V0LWJsb2Nrcy1pbWFnZT0iMGUwYTk0NTE1MjM3ZjExNmYyMGE3NWVjM2JkNDY1YjIiXSB7IG1heC13aWR0aDogMTAwJTsgfSAjdGJjc3MgLndwLWJsb2NrLWltYWdlLnRiLWltYWdlW2RhdGEtdG9vbHNldC1ibG9ja3MtaW1hZ2U9IjBlMGE5NDUxNTIzN2YxMTZmMjBhNzVlYzNiZDQ2NWIyIl0gaW1nIHsgcGFkZGluZy1yaWdodDogMTBweDtwYWRkaW5nLWxlZnQ6IDEwcHg7IH0gLnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfSAjdGJjc3MgLndwLWJsb2NrLWltYWdlLnRiLWltYWdlW2RhdGEtdG9vbHNldC1ibG9ja3MtaW1hZ2U9IjRiN2E4ZjFhYWZjNTU2NWRlYzE4ZGE4Y2QyOTAyNzlmIl0geyBtYXgtd2lkdGg6IDEwMCU7IH0gLnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfSAjdGJjc3MgLndwLWJsb2NrLWltYWdlLnRiLWltYWdlW2RhdGEtdG9vbHNldC1ibG9ja3MtaW1hZ2U9IjBlZGNkMmZhZjgxNTYwZjIzNWY0MjhlMDQ2YWNlNzlmIl0geyBtYXgtd2lkdGg6IDEwMCU7IH0gQG1lZGlhIG9ubHkgc2NyZWVuIGFuZCAobWF4LXdpZHRoOiA3ODFweCkgeyAudGItaW1hZ2V7cG9zaXRpb246cmVsYXRpdmU7dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0ud3AtYmxvY2staW1hZ2UgLnRiLWltYWdlLmFsaWduY2VudGVye21hcmdpbi1sZWZ0OmF1dG87bWFyZ2luLXJpZ2h0OmF1dG99LnRiLWltYWdlIGltZ3ttYXgtd2lkdGg6MTAwJTtoZWlnaHQ6YXV0bzt3aWR0aDphdXRvO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZXtkaXNwbGF5OnRhYmxlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2UgLnRiLWltYWdlLWNhcHRpb257ZGlzcGxheTp0YWJsZS1jYXB0aW9uO2NhcHRpb24tc2lkZTpib3R0b219LnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfS50Yi1pbWFnZXtwb3NpdGlvbjpyZWxhdGl2ZTt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS53cC1ibG9jay1pbWFnZSAudGItaW1hZ2UuYWxpZ25jZW50ZXJ7bWFyZ2luLWxlZnQ6YXV0bzttYXJnaW4tcmlnaHQ6YXV0b30udGItaW1hZ2UgaW1ne21heC13aWR0aDoxMDAlO2hlaWdodDphdXRvO3dpZHRoOmF1dG87dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdle2Rpc3BsYXk6dGFibGV9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbntkaXNwbGF5OnRhYmxlLWNhcHRpb247Y2FwdGlvbi1zaWRlOmJvdHRvbX0udGItaW1hZ2V7cG9zaXRpb246cmVsYXRpdmU7dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0ud3AtYmxvY2staW1hZ2UgLnRiLWltYWdlLmFsaWduY2VudGVye21hcmdpbi1sZWZ0OmF1dG87bWFyZ2luLXJpZ2h0OmF1dG99LnRiLWltYWdlIGltZ3ttYXgtd2lkdGg6MTAwJTtoZWlnaHQ6YXV0bzt3aWR0aDphdXRvO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZXtkaXNwbGF5OnRhYmxlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2UgLnRiLWltYWdlLWNhcHRpb257ZGlzcGxheTp0YWJsZS1jYXB0aW9uO2NhcHRpb24tc2lkZTpib3R0b219LnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfSB9IEBtZWRpYSBvbmx5IHNjcmVlbiBhbmQgKG1heC13aWR0aDogNTk5cHgpIHsgLnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfS50Yi1pbWFnZXtwb3NpdGlvbjpyZWxhdGl2ZTt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS53cC1ibG9jay1pbWFnZSAudGItaW1hZ2UuYWxpZ25jZW50ZXJ7bWFyZ2luLWxlZnQ6YXV0bzttYXJnaW4tcmlnaHQ6YXV0b30udGItaW1hZ2UgaW1ne21heC13aWR0aDoxMDAlO2hlaWdodDphdXRvO3dpZHRoOmF1dG87dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdle2Rpc3BsYXk6dGFibGV9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbntkaXNwbGF5OnRhYmxlLWNhcHRpb247Y2FwdGlvbi1zaWRlOmJvdHRvbX0udGItaW1hZ2V7cG9zaXRpb246cmVsYXRpdmU7dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0ud3AtYmxvY2staW1hZ2UgLnRiLWltYWdlLmFsaWduY2VudGVye21hcmdpbi1sZWZ0OmF1dG87bWFyZ2luLXJpZ2h0OmF1dG99LnRiLWltYWdlIGltZ3ttYXgtd2lkdGg6MTAwJTtoZWlnaHQ6YXV0bzt3aWR0aDphdXRvO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZXtkaXNwbGF5OnRhYmxlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2UgLnRiLWltYWdlLWNhcHRpb257ZGlzcGxheTp0YWJsZS1jYXB0aW9uO2NhcHRpb24tc2lkZTpib3R0b219LnRiLWltYWdle3Bvc2l0aW9uOnJlbGF0aXZlO3RyYW5zaXRpb246dHJhbnNmb3JtIDAuMjVzIGVhc2V9LndwLWJsb2NrLWltYWdlIC50Yi1pbWFnZS5hbGlnbmNlbnRlcnttYXJnaW4tbGVmdDphdXRvO21hcmdpbi1yaWdodDphdXRvfS50Yi1pbWFnZSBpbWd7bWF4LXdpZHRoOjEwMCU7aGVpZ2h0OmF1dG87d2lkdGg6YXV0bzt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS50Yi1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbi1maXQtdG8taW1hZ2V7ZGlzcGxheTp0YWJsZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9ue2Rpc3BsYXk6dGFibGUtY2FwdGlvbjtjYXB0aW9uLXNpZGU6Ym90dG9tfS50Yi1pbWFnZXtwb3NpdGlvbjpyZWxhdGl2ZTt0cmFuc2l0aW9uOnRyYW5zZm9ybSAwLjI1cyBlYXNlfS53cC1ibG9jay1pbWFnZSAudGItaW1hZ2UuYWxpZ25jZW50ZXJ7bWFyZ2luLWxlZnQ6YXV0bzttYXJnaW4tcmlnaHQ6YXV0b30udGItaW1hZ2UgaW1ne21heC13aWR0aDoxMDAlO2hlaWdodDphdXRvO3dpZHRoOmF1dG87dHJhbnNpdGlvbjp0cmFuc2Zvcm0gMC4yNXMgZWFzZX0udGItaW1hZ2UgLnRiLWltYWdlLWNhcHRpb24tZml0LXRvLWltYWdle2Rpc3BsYXk6dGFibGV9LnRiLWltYWdlIC50Yi1pbWFnZS1jYXB0aW9uLWZpdC10by1pbWFnZSAudGItaW1hZ2UtY2FwdGlvbntkaXNwbGF5OnRhYmxlLWNhcHRpb247Y2FwdGlvbi1zaWRlOmJvdHRvbX0gfSA=

Parts

Boiler Parts

We carry an extensive inventory of Columbia, Fulton, Reimers, Pacific Steam, and Sussman boiler parts. We stock burners, controls, gas trains and other parts. We can also build conversion burners to convert your boiler from oil to gas or vice versa.

We are distributors for products made by many different brands, please see below for a list of common brands we sell. We keep the majority of parts we offer in stock for immediate pickup or shipment. We ship packages daily with UPS.

Pressing Machine Parts

Before you let someone tell you there are no parts available for your machine, please call us.

Our parts department also specializes in used hard-to-find parts for Hoffman and New Yorker pressing machines. We realize that the machines made today are not the same quality as the machines made years ago. Rather than discard your old machine, repair it.

We have a full inventory of everything from pedals, springs, linkage pieces, shock absorbers, pressing machine bucks and heads, to air cylinders, and valves for older air machines.

Rema Dri-Vac

Air vacuums and condensate return tanks.

Fulton Boiler Works

Parts for both oil and gas fired boilers.

Labtest Products

Premium press pads and grid plates.

Reimers Electra Steam

Electric steam generator parts including elements and contactors.

Cissell

May be out of business, but we have sourced many of the replacement parts for spotting boards, form finishers and puffers.

Lattner Boilers

We have parts in stock for both electric and gas fired Lattner boilers. We also have Lattner Blowdown tanks in both new and refurbished.

United Brass

United Brass manufactures parts for steam pressing machines, as well as installation valves and check valves.

Sussman

Parts for electric boilers including heating elements, steam tunnels, and vacuum tables.

Hashima

Fusing machine parts including belts, motors and heating elements.

Burkes Pumps

Water feed pumps for high pressure steam boilers.

Reliable

Mini boilers, and steam electric irons.

In addition to these leading manufacturers, we also have a variety of support items including Spirax Sarco and Armstrong steam traps, a variety of both all steam and steam electric irons and parts including hoses and shoes, assorted valves, check valves and safety valves plus many other items.

Service

Break Downs cost you money – Our service department features factory trained technicians and stocked parts vans that cover the tri-state area daily. Since down time costs you money, we do our best to accommodate same day emergency service to get you back up and running quickly. Our vans are mobile parts departments stocked with the most common boiler parts for Fulton, Columbia, Lattner, Reimers, Pacific Steam and Sussman boiler. We also stock parts for steam presses, Cissell products, and other items such as irons, hoses, valves and traps. In addition to our local service technicians, we have developed a nation-wide network of technicians to help us across the country with servicing the equipment we sell.

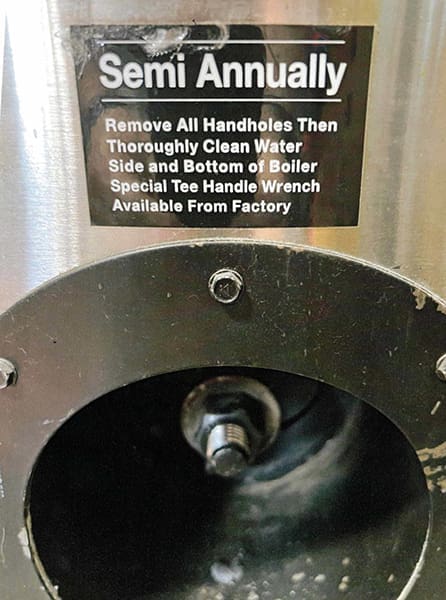

The best way to avoid an emergency service call is to schedule preventive maintenance calls. Most boiler manufacturers recommend opening the pressure vessel 2x per year. We make our boiler inspection appointments first call, so you can minimize your down time. We also perform state/insurance inspections with your inspector. At the point of the boiler inspection, our mechanic can also go over your pressing equipment and make any repairs or adjustments while he is there instead of paying a second time to come back for another issue.

Preventative maintenance recommendations for gas steam boilers

Daily:

- Check all switches for proper operation

- Check sight glass for water level and water clarity

- Check entire system and piping for leaks or corrosion

- Check water tank and water level in same

- Check tank vent for excessive steam loss

- Flush all drain valves for 20 seconds and make sure all are clear

- Check boiler pressure setting

Weekly:

- Fully drain entire system and check for leaks

Semi-annually:

- Open boiler hand hole openings and inspect for scale or corrosion

- Remove water probes and clean same

- Remove burner and check settings, clean and reset same

- Check steam safety valve, feed pump and pressure controls

- Check all switches and contacts for corrosion

- Check all safety systems and flue for proper operation

- Change sight glass and washers

- Install new gaskets as needed

- Check flame for proper setting and clean burning of fuel

- Check for any loose or exposed wiring

Annually:

- Follow all semi annual procedures as listed above

- Replace water probes

- Replace ignition electrodes

- Replace check valves on pump line

- Check combustion of burner and inspect flue for soot or blockage

- Check boiler room for cleanliness and ventilation

- check low water cut off system for proper operation

- check feedwater inlet to boiler

- open and clean out condensate return system

Boiler should have internal insurance inspection annually.

Spare parts needed: Handhole gaskets, Handhole plate, water probes, ignition electrodes, sight glass and gaskets, steam safety valve, spring check, swing check, tank gasket and float valve, contactor, and drain valve.

Preventative maintenance recommendations for electric steam boilers

Daily:

- Check site glass water level

- Check electrical controls

- Check for leaks

- Flush system briefly

Weekly:

- Fully drain system

- Check around boiler for dirt, dust or lint and clean same

Semi-annually:

- Remove and clean heating elements

- Remove and clean water probe(s)

- Check pressure switches and low water cut-off

- Change sight glass and washers

- Check for loose or exposed wiring

Annually:

- Check electrical switches and close/lock out same

- Fully drain boiler making sure all drain lines are clear

- Drain and open feed water tank if present and check and clean float valve

- Disconnect, remove and inspect heating elements, replace if scale present

- Check all contacts and pressure switches for wear, replace if necessary

- Flush and clean internal shell of boiler

- Check feed pump, check valves and feed lines, replace if corroded

- Clean strainers and lines

- Pressure test system for leaks

- List any abnormal conditions and report same.

- Check Low water cut off system for proper operation

Boiler should have internal insurance inspection annually.

Spare parts kept on site should include all gaskets, glass and washers, check valve, pressure switches, element, contractor, water probe, and plumbers tape.

Preventative maintenance recommendations for steam pressing machines

Daily:

- Check press for steam or water leaks at start up

- Check contact adjustment between top and bottom press surfaces

- Check press pad and cover for dirt, tears or lumps

- Check for loose parts or connections

- Check steam iron valve, hoses and iron shoe

Semi-annually:

- Replace press pad

- Replace iron shoe and iron hoses

- Check and lubricate vacuum and check tank drain

Annually:

- Replace head valve spring and steam disk

- Replace buck valve disk and check spring tension

- Change vacuum valve plunger and spring

- Check press hoses and all connections for leaks or corrosion

- Check top press plate and replace if needed

Spare parts: Press pad, press plate, iron valve, iron shoe, iron hoses, hose cover, Head valve spring and disc, buck valve disc, vacuum plunger and spring, press hose and gasket, roller bearing, left and right ball joint, helper spring, and plumbers tape.

Seickel Warranty

Seickel and Sons, Inc.

June 16, 2019

Warranty Procedures

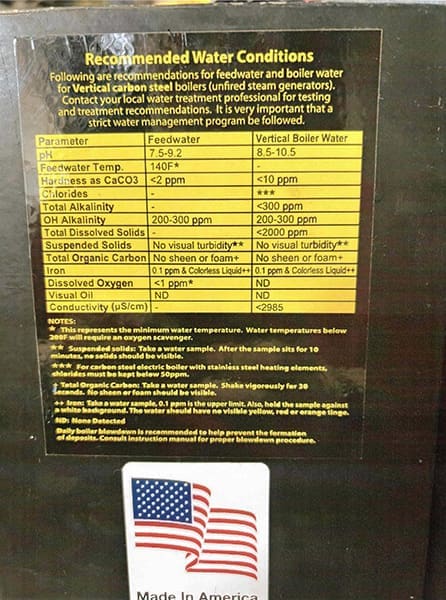

Seickel & Sons, Inc offers a 1 year parts and 90 day labor warranty on all equipment and parts sold directly by Seickel & Sons, Inc to end users. This warranty does not apply to any electrical parts, which are subject to Manufacturer’s Warranty Only. Warranties are voided if an end user has anyone aside from Seickel & Sons, Inc employees do maintenance or repairs to the subject equipment. Also, in the case of gas fired, oil fired, or electric steam boilers, proper water treatment as per the Manufacturer’s Specs must be adhered to as well as 6 month inspections on the equipment to insure proper operation and maintenance procedures are followed.

Any deviation from these procedures can void the product warranty.

Any questions with regards to these procedures can be handled by Ryan Seickel in our service department or directly to Joseph Seickel, president of Seickel & Sons, Inc at 1-800-338-5044.