Seickel & Sons is a leader in steam processing

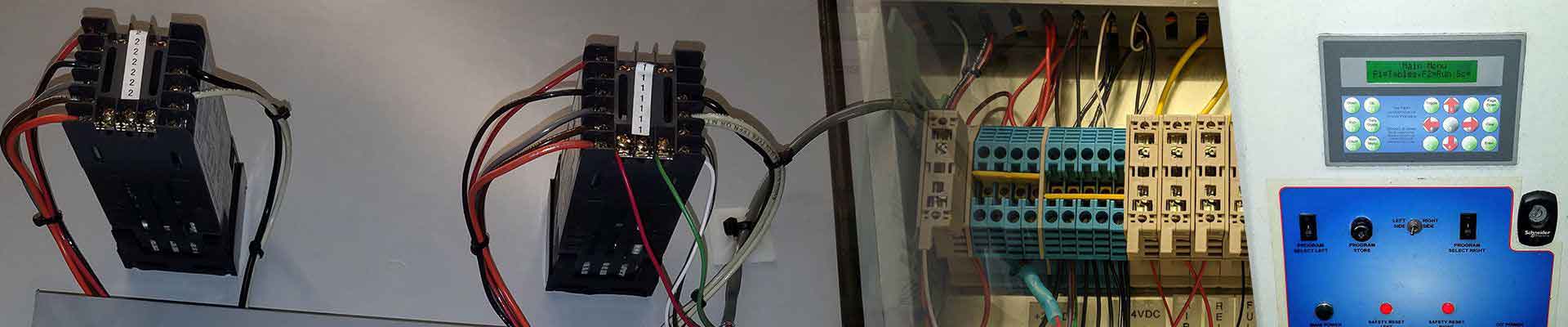

We sell, service and install high and low pressure steam systems for manufacturing processes

We have amassed an extensive amount of unique knowledge about steam systems regarding what does and doesn’t work. We started the company refurbishing and installing steam pressing equipment and boilers for use in garment manufacturing and alteration rooms. Through the thousands of jobs we have done setting up factories in the garment industry, we have been able to transfer and use those skills to assist companies in many other industries, which now makes up the bulk of our work.

We have built custom steam equipment for use in the automotive industry for removing wrinkles from new car seats and trim. We have repaired and updated many outdated, automated equipment for customers in the cosmetic and boiler manufacturing industries, so they can still be used in production. We have done many one-off custom fabrication jobs and installed jacketed steam kettles for customers in the cosmetic, food, craft brewing, and distillation industries.

Please visit our Industries or Case Studies pages for examples of the industries we are experienced in and some of the specific jobs we have done.

We have even rented equipment for use in television and movies sets and have done special effect work for businesses looking to add some flair to their storefronts.

We have a full machine shop at our Middlesex, NJ location that can modify or construct custom steam manifolds to be retrofitted on existing equipment or installed as standalone units. We have also designed and built machinery from scratch.

After 80 years of getting jobs done the right way, Seickel & Sons Inc. has the knowledge and the experience to assist you in any way with your steam systems and associated equipment.

We travel across the country and further to consult, design, install, and service our steam systems. We even hold patents on our machinery.

We are authorized Sales representatives for Columbia, Fulton, and Reimers Boiler. We are also authorized to install and perform service on their equipment.

Boilers require preventative maintenance, and selecting the right company to conduct this maintenance is one of the best ways to make sure your equipment is getting the kind of attention it needs. Please visit our Parts and Service page for recommended service intervals and inspection information for your steam boilers.

Call us today to schedule maintenance on your steam equipment to protect your investment and help avoid costly production shutdowns.

Mention you are a new customer and receive a 10% discount on your first service. Call today 732-624-9070!

How Seickel & Sons can provide service

Si tiene alguna pregunta o consulta por favor no dude en contactarnos directamente al 732-624-9070.

Estaremos muy a gusto de poder servirles

We service what we sell

We have a large selection of used parts for Hoffman, New Yorker and Cissell steam pressing machines including parts someone else told you they can’t get anymore – trust us, we have it. We have everything from heads and bucks to linkage parts, valves, cylinders shafts and levers. We are also a stocking distributor for Columbia Boiler, Reimers Electra Steam Boiler, Fulton Boiler, Rema Dri-Vac and LabTest products.

We service the Tri-state area and beyond with our own team of factory trained technicians. Our technicians have stocked service vehicles so we can fix your equipment when we arrive the first time. We also have a nationwide network of service techs we can call on for service needs outside of our area.

*Seickel & Sons is not affiliated with Hoffman and New Yorker, nor do we rely on them for replacement parts.